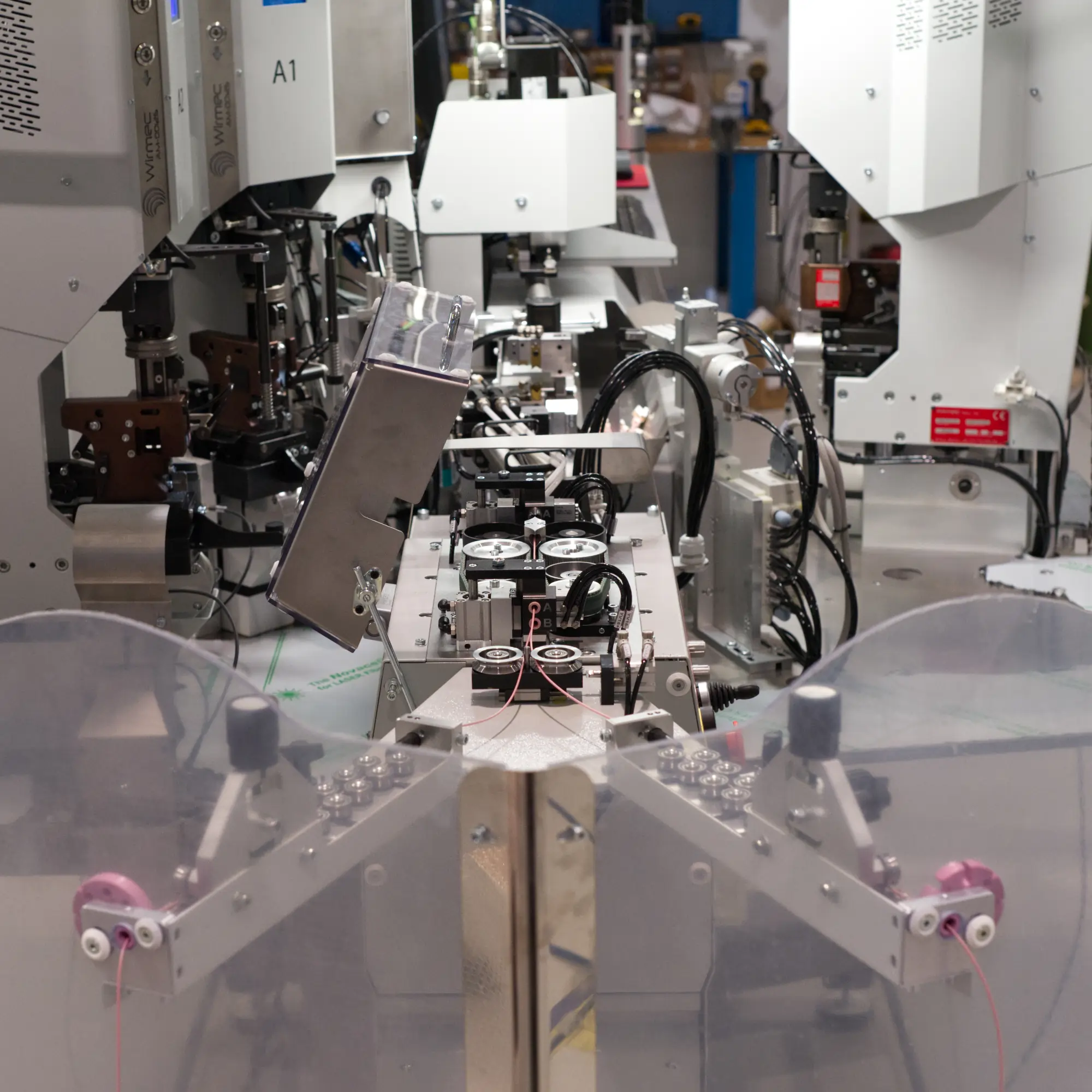

Cut strip and terminale automatic machine that can be equipped with up to six processing stations.

Thanks to the integration of the new patented system for the processing of two different cables, it is proposed as an innovative and technological machine.

EQUIPMENT:

• CE norms compliance;

• Equipment up to six stations ;

• Wire feeder convetible from rollers to belts drive;

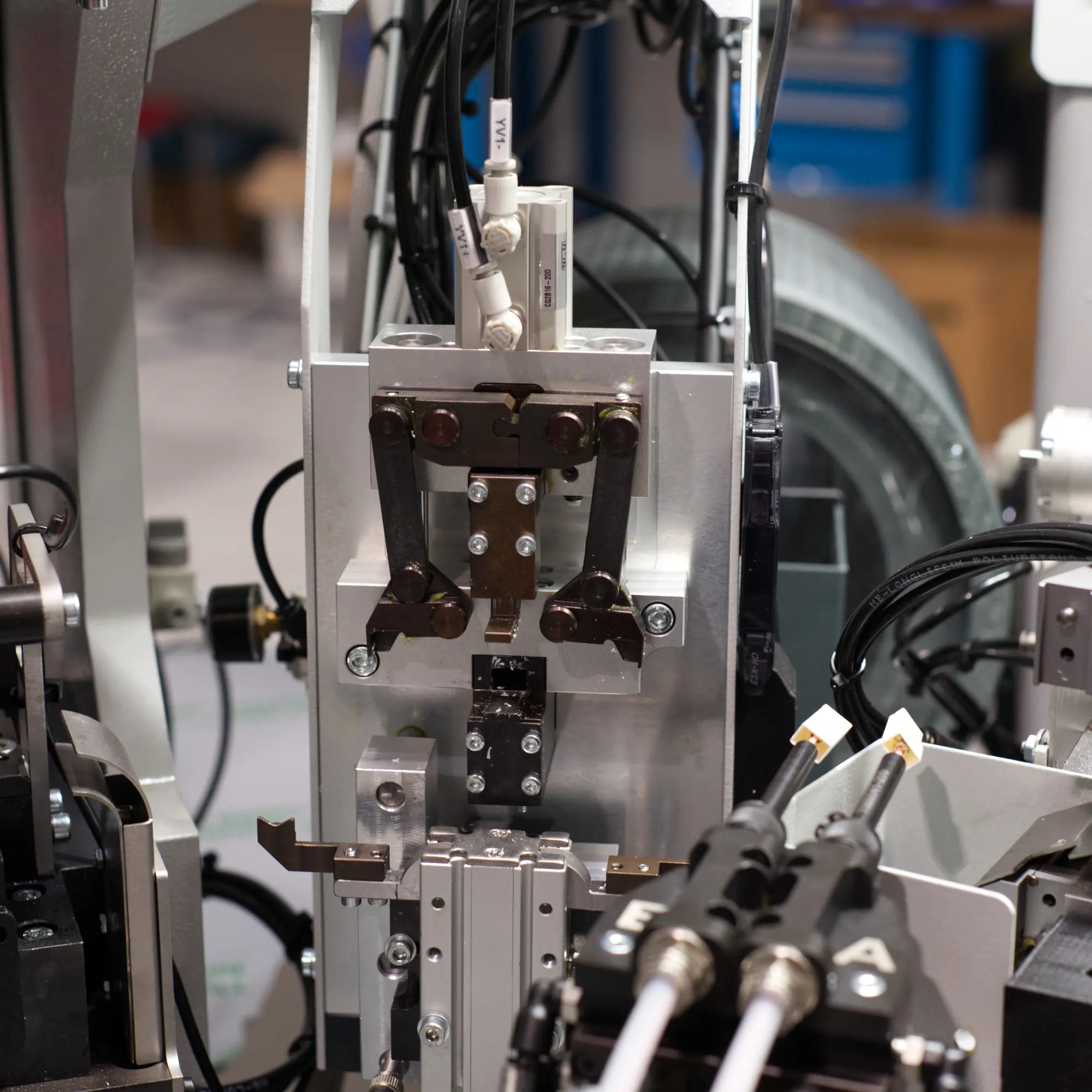

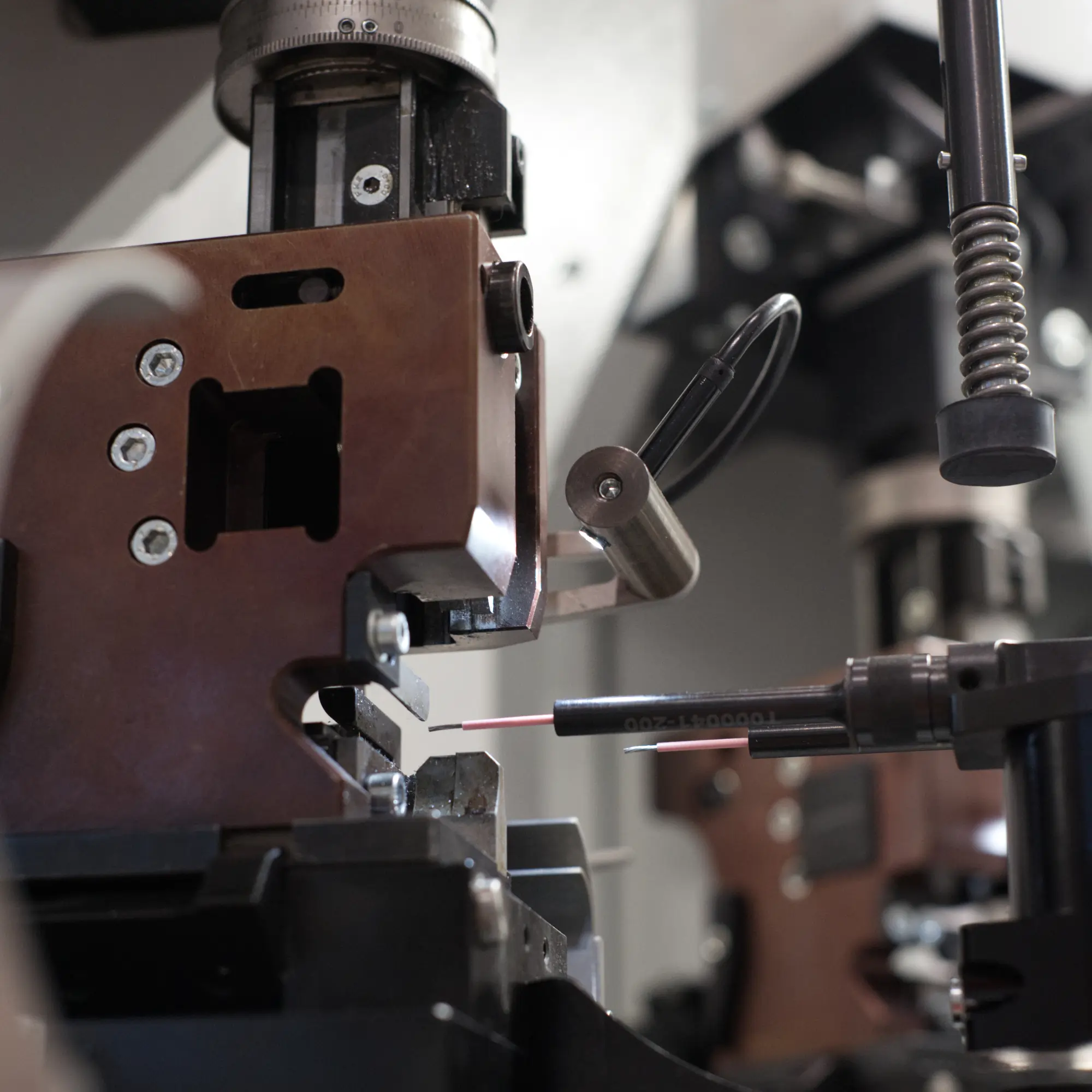

• Programmable cuttin head;

• Programmabile doubling unit with longitudinal offset on upper wire that can be saved on interface recipe;

• Double straighten unit with memorizable position;

• Wire guides Ø1,3, Ø1,7, Ø2, Ø2,5, Ø3, Ø4;

• Maintenance kit;

• Upward safety guard;

• Scraps box;

• Operator consolle with storage rack and drawings;

• PC 21” wide monitor;

• Vision interface in local language;

• Wi-Fi, Ethernet and USB connection;

• Steel frame in Italian Style;

• Use and maintenance manuals;

Thanks to the integration of the new patented system for the processing of two different cables, it is proposed as an innovative and technological machine.

EQUIPMENT:

• CE norms compliance;

• Equipment up to six stations ;

• Wire feeder convetible from rollers to belts drive;

• Programmable cuttin head;

• Programmabile doubling unit with longitudinal offset on upper wire that can be saved on interface recipe;

• Double straighten unit with memorizable position;

• Wire guides Ø1,3, Ø1,7, Ø2, Ø2,5, Ø3, Ø4;

• Maintenance kit;

• Upward safety guard;

• Scraps box;

• Operator consolle with storage rack and drawings;

• PC 21” wide monitor;

• Vision interface in local language;

• Wi-Fi, Ethernet and USB connection;

• Steel frame in Italian Style;

• Use and maintenance manuals;

• Wire cross section: 0,13—2,5mm² (4mm² option)

• Wire length: 42mm crimp side A

55mm crimp both side

• Resolution: ±(0.2% +1mm)

• Stripping length: 1— 15mm (more option)

• Wire speed: 8.5m/s

• Power supply: 400V 50Hz—9kVA

• Air supply: 6-7 bar

• Air consumption: 60l/min

• Weight: ~1100Kg base machine

• Noise: <75dB (without presses)

• Dimensions: W4000 x D1800 x H2000mm

• Wire length: 42mm crimp side A

55mm crimp both side

• Resolution: ±(0.2% +1mm)

• Stripping length: 1— 15mm (more option)

• Wire speed: 8.5m/s

• Power supply: 400V 50Hz—9kVA

• Air supply: 6-7 bar

• Air consumption: 60l/min

• Weight: ~1100Kg base machine

• Noise: <75dB (without presses)

• Dimensions: W4000 x D1800 x H2000mm

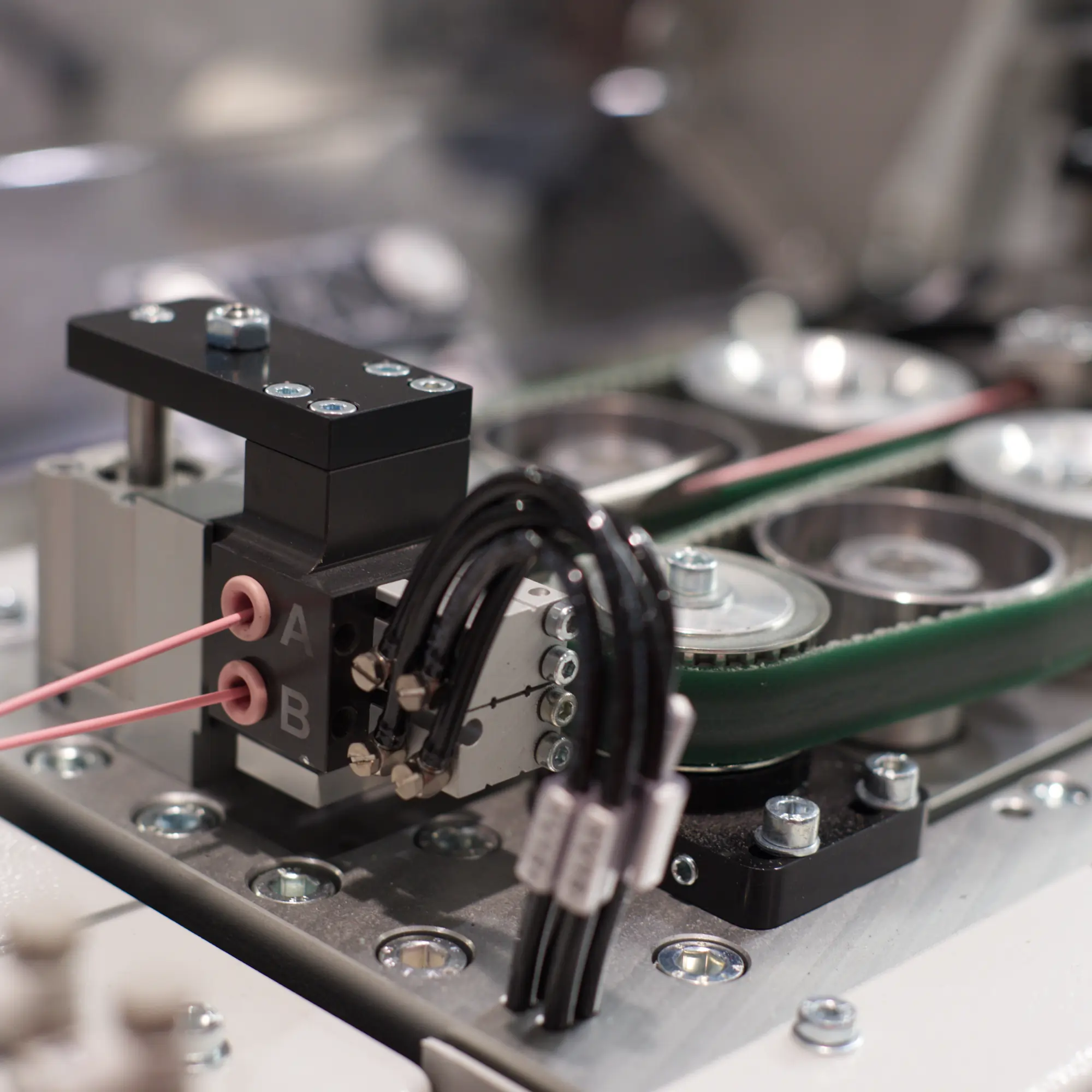

• Crimping unit with electronic crimp height adjustment;

• Videocamera for easy wire positioning on crimping units on side A;

• Integrated on Vision interface pull test;

• Integrated on Vision interface crimp height gauge;

• Touchscreen monitor;

• Paper winder;

• Programmable end reel terminals and anti jam

detection system;

• Interchangeable belt drive kit;

• Wire deposit unit 2m prolung;

• Working area lighting;

• Quick tool applicator;

• Integrated digital microscoper 500X

• Videocamera for easy wire positioning on crimping units on side A;

• Integrated on Vision interface pull test;

• Integrated on Vision interface crimp height gauge;

• Touchscreen monitor;

• Paper winder;

• Programmable end reel terminals and anti jam

detection system;

• Interchangeable belt drive kit;

• Wire deposit unit 2m prolung;

• Working area lighting;

• Quick tool applicator;

• Integrated digital microscoper 500X