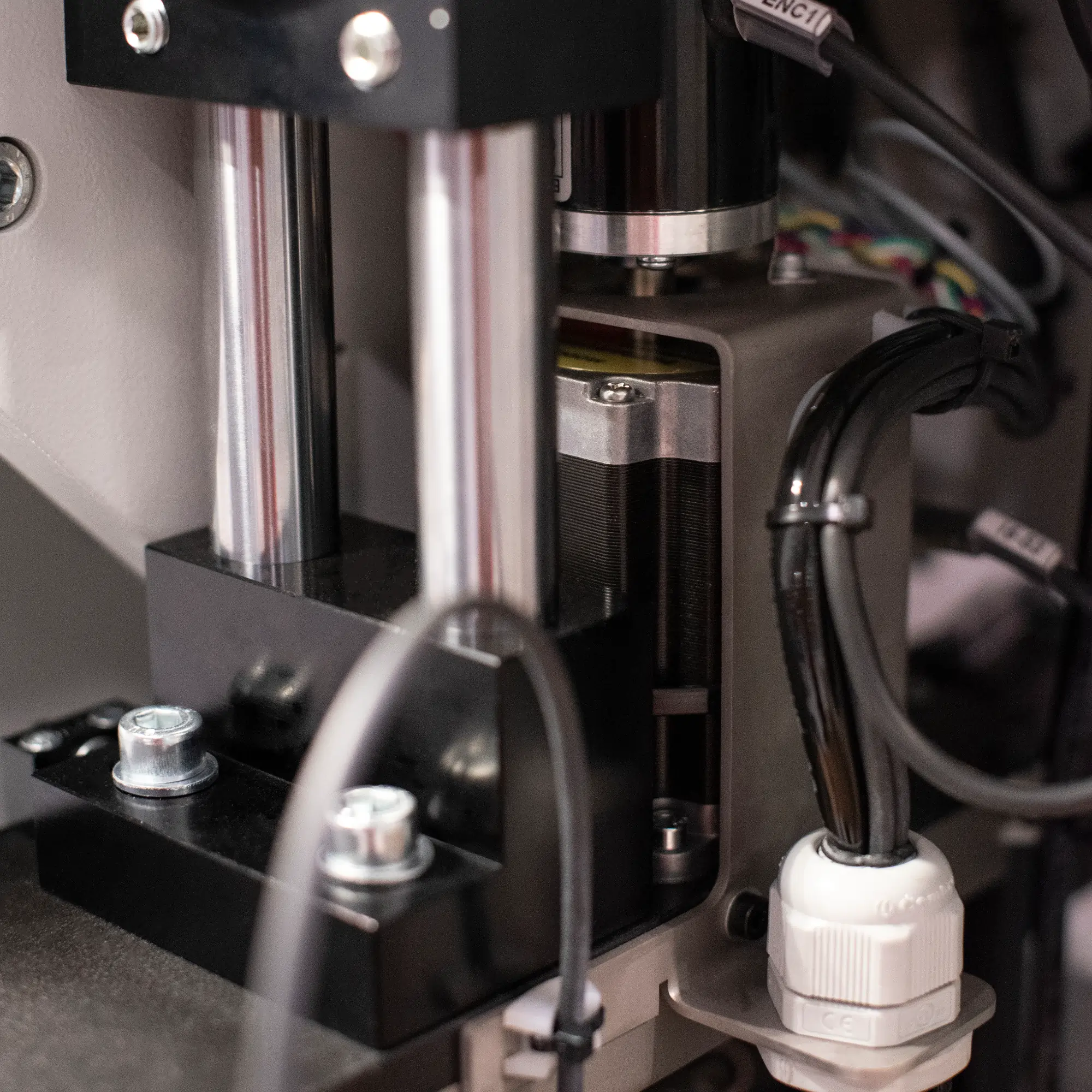

The WSC21 electronic stripper crimper is the best seller of wide range of products by Wirmec. The two patented systems, on the stripping head and the crimping gripper guard, have allowed it to reach such high levels of precision and quality that it is one of the most highly regarded in the electrical wiring market.

The Wirmec Vision operator interface on monitor touch screen 7”, facilitates the operator in the parameter management and machining programming stages.

Many options are available to make it flexible to multiple processing.

CHARACTERISTICS:

• CE norms compliance;

• Programmable wire cross section and stripping length;

• Settings processing on recipe;

• Scrap vacuum system;

• Programmable terminal ejector;

• Terminal ejector position adjustable by videocamera;

• Way back system;

• Double zero cut;

• Adjustable stripping speed;

• Quick change stripping blades;

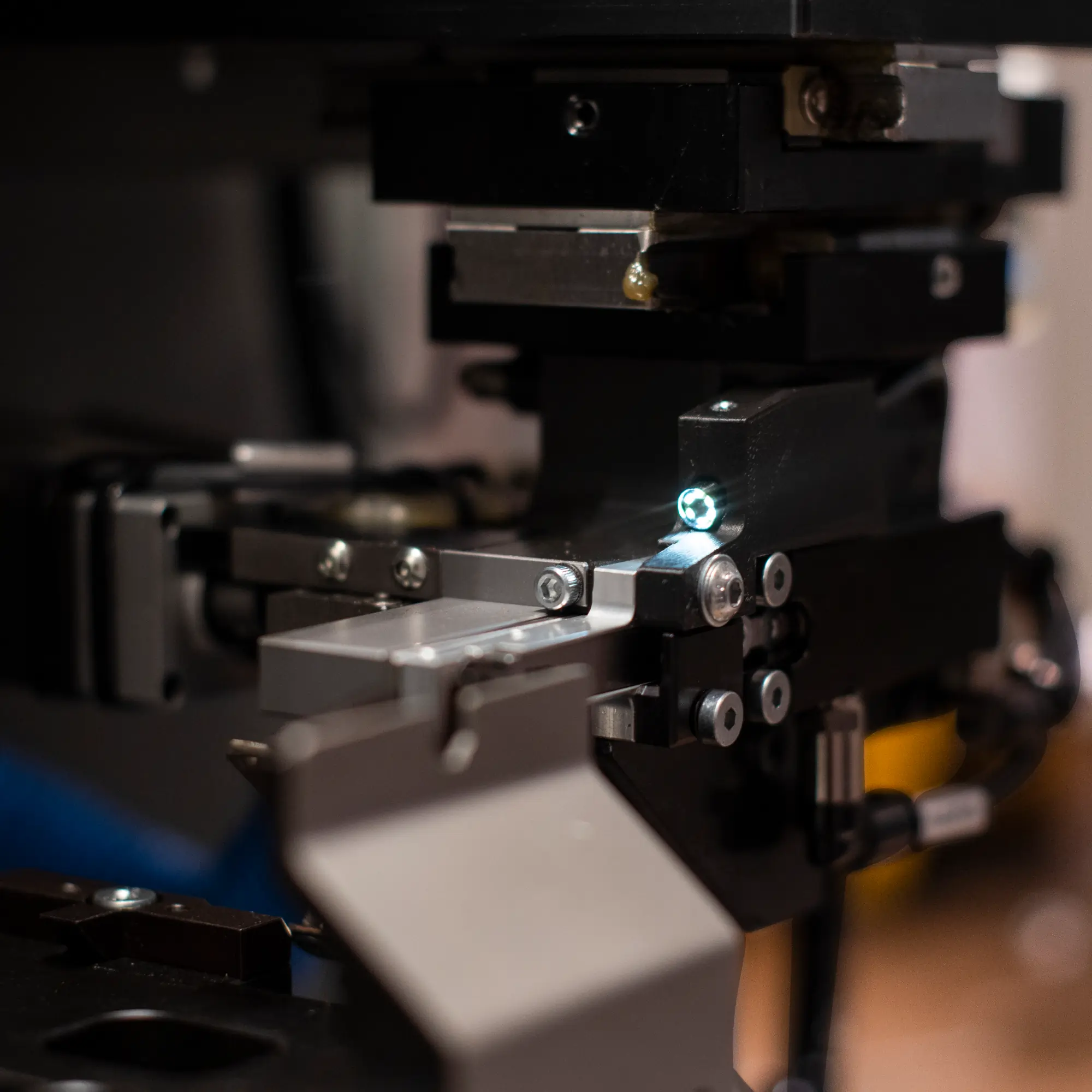

• Working area lighted;

• Stripper module height adjustable;

• Wire funnel Ø1,8 and Ø4mm;

• Scraps box;

• Monitor touch wide screen 7”;

• Vision interface in local language;

• Wi-Fi, Ethernet and USB connection;

• Italian Style frame;

• Use and maintenance manual;

The Wirmec Vision operator interface on monitor touch screen 7”, facilitates the operator in the parameter management and machining programming stages.

Many options are available to make it flexible to multiple processing.

CHARACTERISTICS:

• CE norms compliance;

• Programmable wire cross section and stripping length;

• Settings processing on recipe;

• Scrap vacuum system;

• Programmable terminal ejector;

• Terminal ejector position adjustable by videocamera;

• Way back system;

• Double zero cut;

• Adjustable stripping speed;

• Quick change stripping blades;

• Working area lighted;

• Stripper module height adjustable;

• Wire funnel Ø1,8 and Ø4mm;

• Scraps box;

• Monitor touch wide screen 7”;

• Vision interface in local language;

• Wi-Fi, Ethernet and USB connection;

• Italian Style frame;

• Use and maintenance manual;

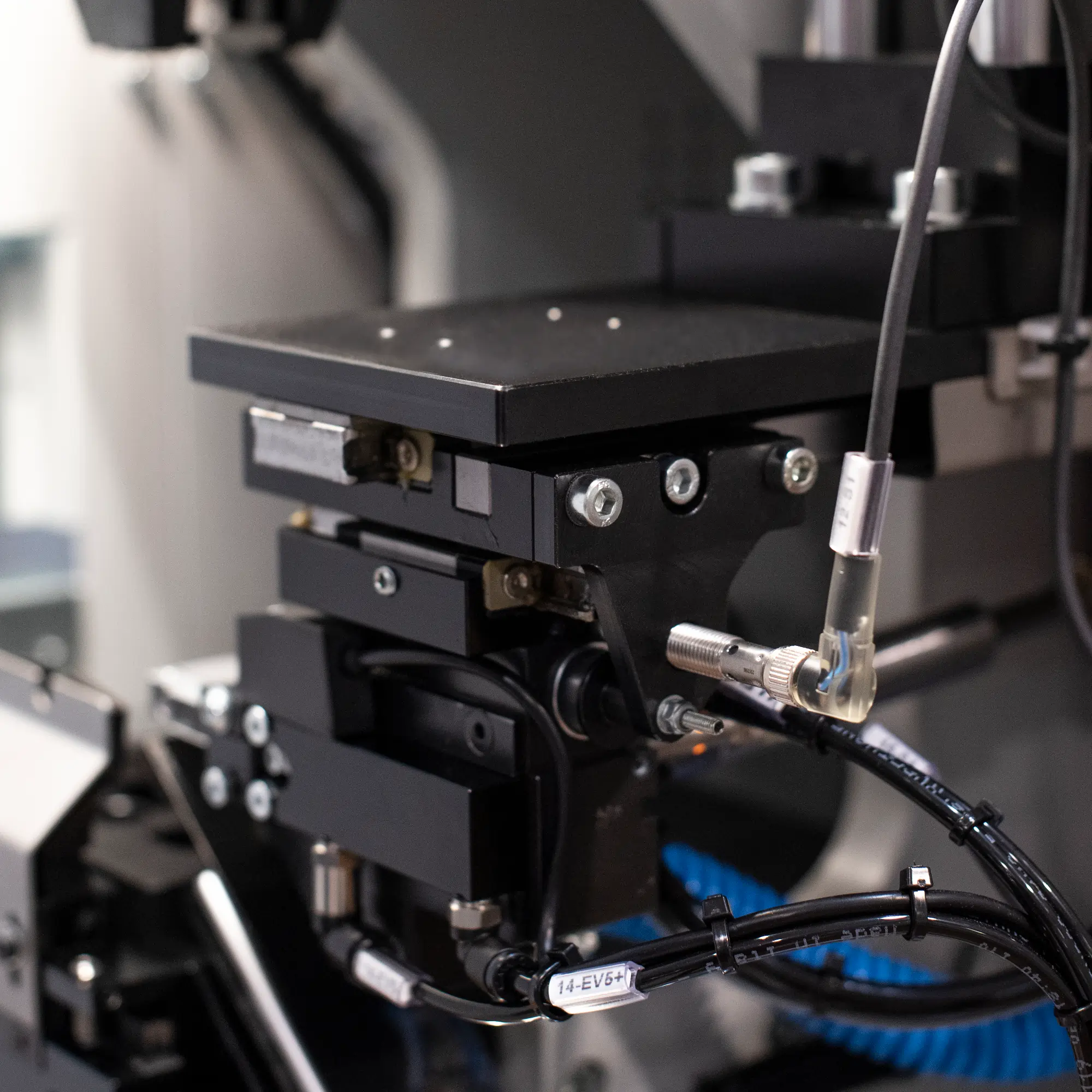

Crimping press:

• Crimp force: 20 kN

• Wire cross section: 0.08 – 6 mm² (AWG 28 – AWG 10)

• Shut height: 135,78 mm

• Power supply: 1 x 230 V / 50 Hz

• Air supply: 6 – 7 bar

• Air consumption: 25 l/min (with vacuum)

• Weight: ~90 Kg

• Noise: <75 dB (without vacuum)

• Dimensions: W 450 x D 500 x H 750 mm

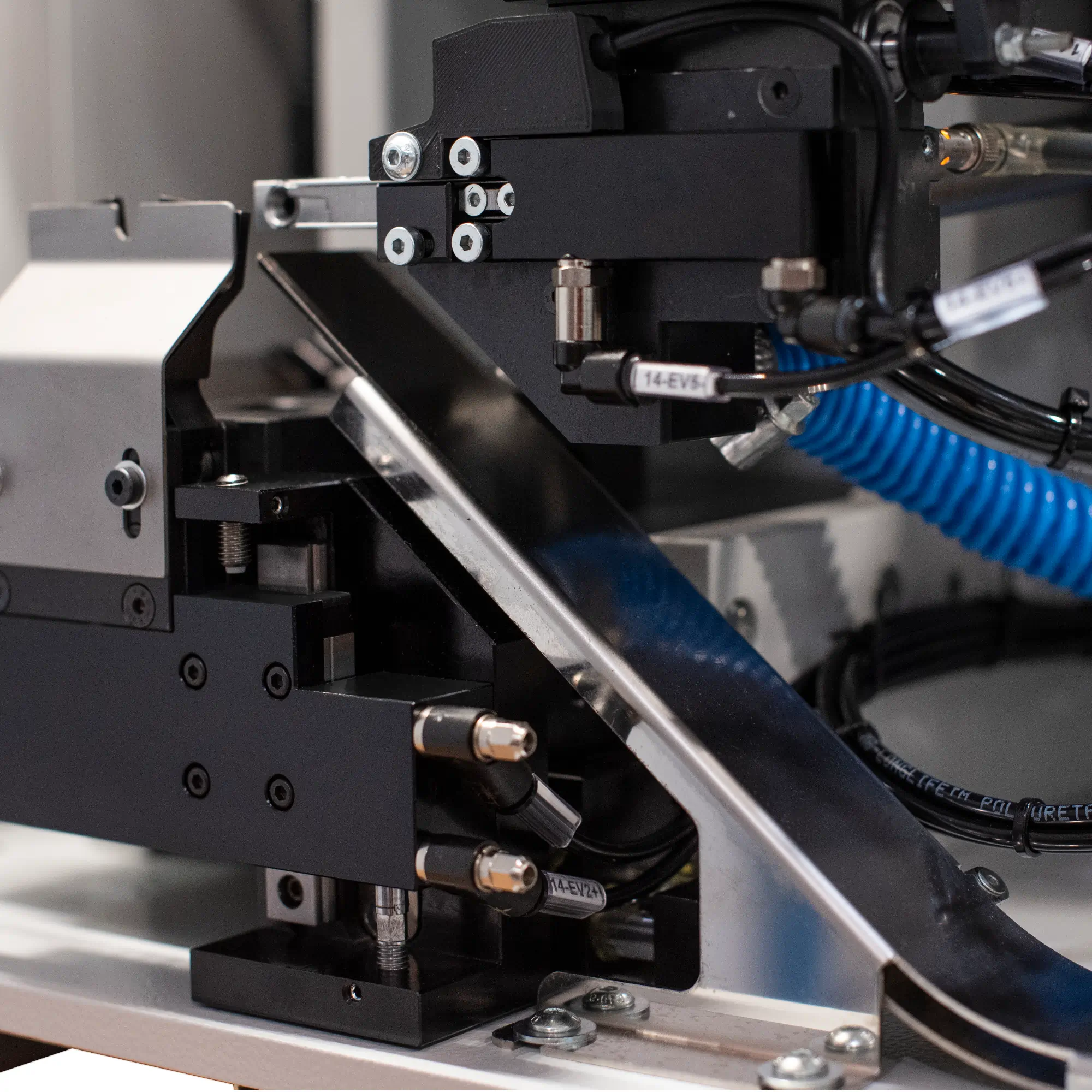

Stripping module:

• Wire cross section: 0,08 – 4 mm² (AWG 28 -AWG 11)

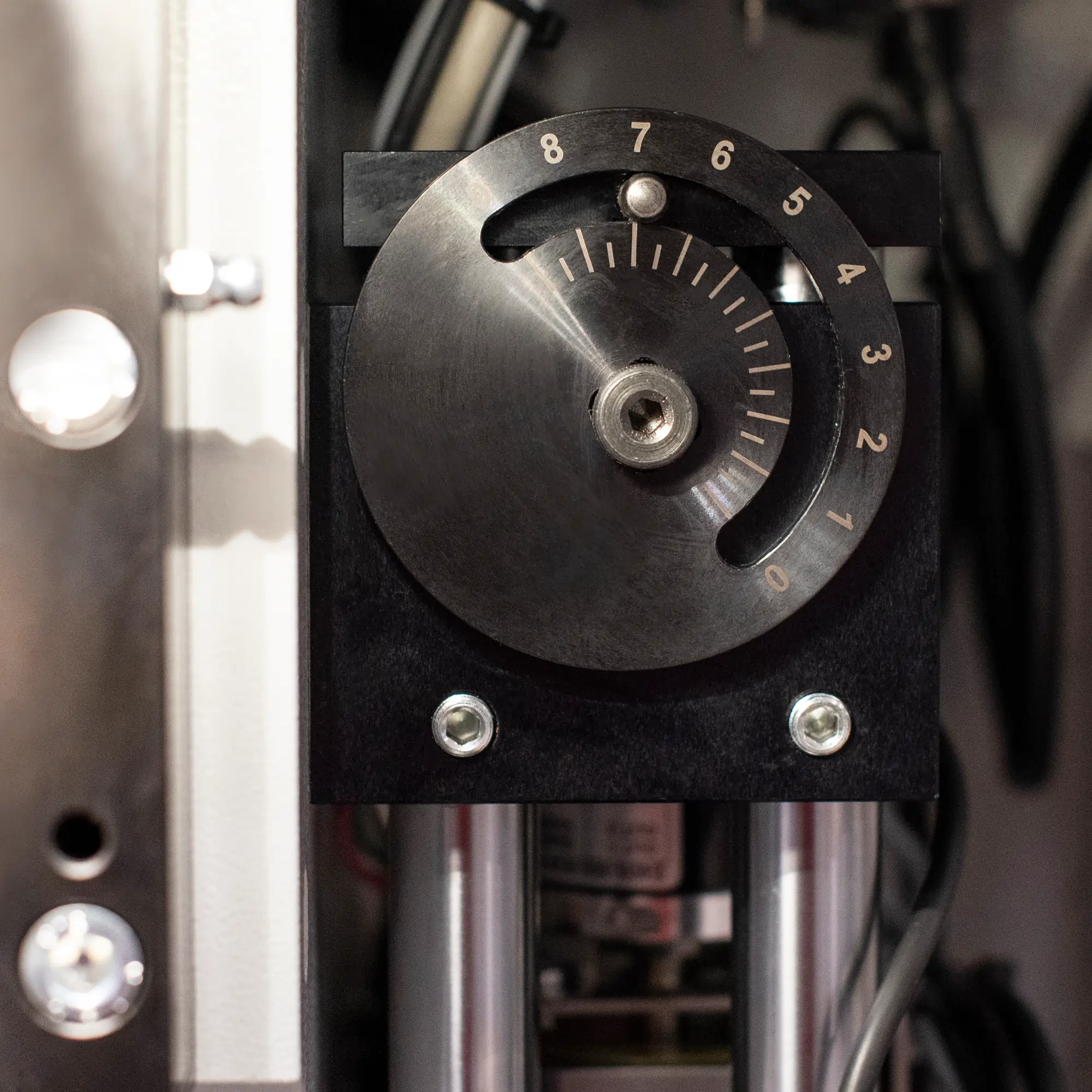

• Strip lenght: 1 – 11 mm (more option)

• Wire length: Min 18 mm (lower option)

• Zero cut lenght: max 8 mm – wire cross section max 2.5 mm²

• Cycle time: 0.83 s with crimp, without wayback

• Crimp force: 20 kN

• Wire cross section: 0.08 – 6 mm² (AWG 28 – AWG 10)

• Shut height: 135,78 mm

• Power supply: 1 x 230 V / 50 Hz

• Air supply: 6 – 7 bar

• Air consumption: 25 l/min (with vacuum)

• Weight: ~90 Kg

• Noise: <75 dB (without vacuum)

• Dimensions: W 450 x D 500 x H 750 mm

Stripping module:

• Wire cross section: 0,08 – 4 mm² (AWG 28 -AWG 11)

• Strip lenght: 1 – 11 mm (more option)

• Wire length: Min 18 mm (lower option)

• Zero cut lenght: max 8 mm – wire cross section max 2.5 mm²

• Cycle time: 0.83 s with crimp, without wayback

• Industry 4.0 compliance

• Crimp force monitoring (CFM)

• Electronic crimp height adjustment

• Wire length less 18 mm

• Cut bad crimp

• Wire sequence

• Wire color detection

• Wire shortening cycle

• Terminals oiler kit

• Bad crimp box

• Stripping quality check cycle

• Paper wind device

• Carrier strip chopper

• Foot switch

• Motorized terminals de-reeler

• Double wire crimp

• Crimp force monitoring (CFM)

• Electronic crimp height adjustment

• Wire length less 18 mm

• Cut bad crimp

• Wire sequence

• Wire color detection

• Wire shortening cycle

• Terminals oiler kit

• Bad crimp box

• Stripping quality check cycle

• Paper wind device

• Carrier strip chopper

• Foot switch

• Motorized terminals de-reeler

• Double wire crimp